Wire Drawing requiers Lubrication

Lube Line is used in the process of wire drawing. It facilitates the drawing operation by providing stable lubrication, reducing friction, and preventing deposits on dies and wire surfaces. This leads to smoother processing, extended die life, and consistent wire quality.

Short description of the process

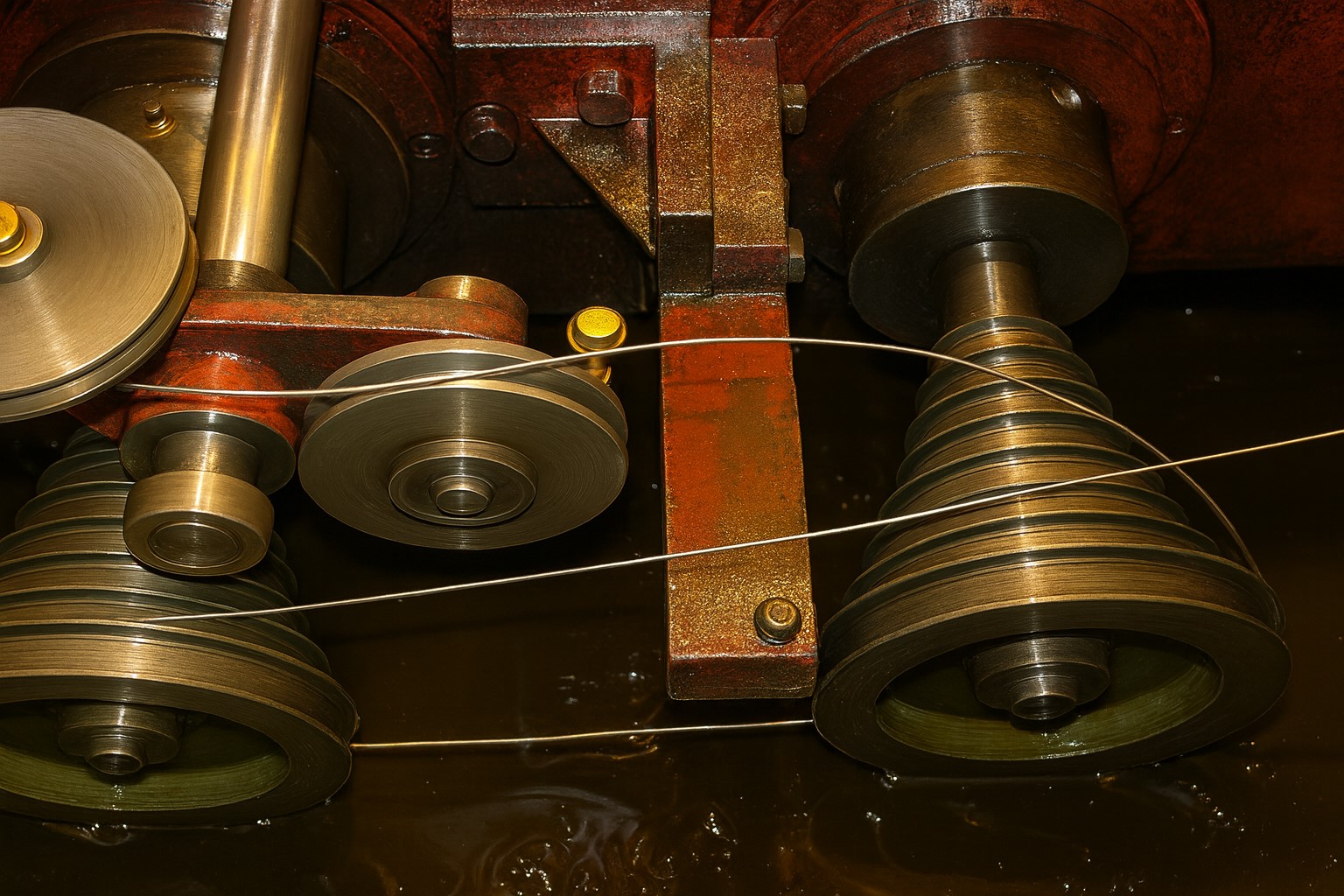

In a wire drawing mill, thick metal rod – such as copper, aluminium, or steel – is first cleaned and coated with a lubricant carrier. The rod is then pulled through a series of progressively smaller dies, which gradually reduce its diameter while increasing its length. Lubrication is applied throughout to reduce friction and ensure a smooth surface. Between reductions, the wire passes over capstans that maintain the pulling force and speed. If required, the wire is annealed during or after drawing to restore ductility and achieve the desired electrical or mechanical properties. Finally, the finished wire is collected on spools or coils, ready for further use in cables, springs, or industrial products. These mills provide the essential components for electrical wiring, reinforcement materials, and countless precision applications. Advanced techniques ensure consistent quality, high tensile strength, and surface finish, while modernization focuses on efficiency and reduced waste.