Welcome to Lucent Chemicals

We are Head Group

HEAD Group unites three specialized companies with complementary strengths:

Applications

Our strength is the ability to tailor and customize process solutions for the industry, using a combination of surface chemistry and thermomechanical technologies.

Aluminium Foil

Cold rolling is the process of passing aluminium through rollers. It reduces thickness and the result is aluminium sheet or foil with high precision and quality.

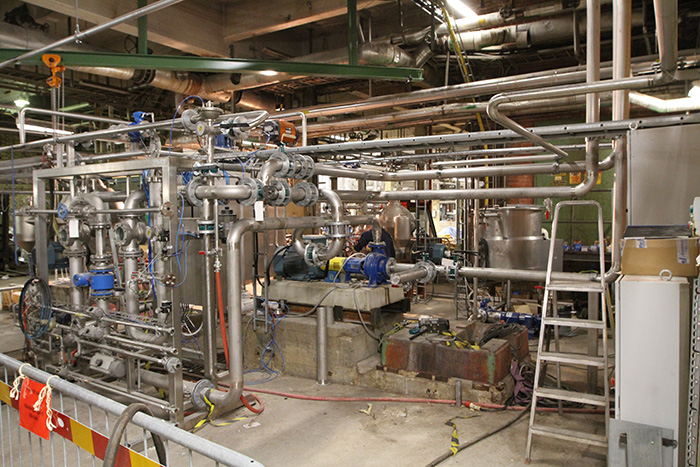

Oil Recovery

Slop oil plants treat oil-contaminated wastewater using heat, chemicals, and mechanical separation to recover oil, clean water, and remove solids.

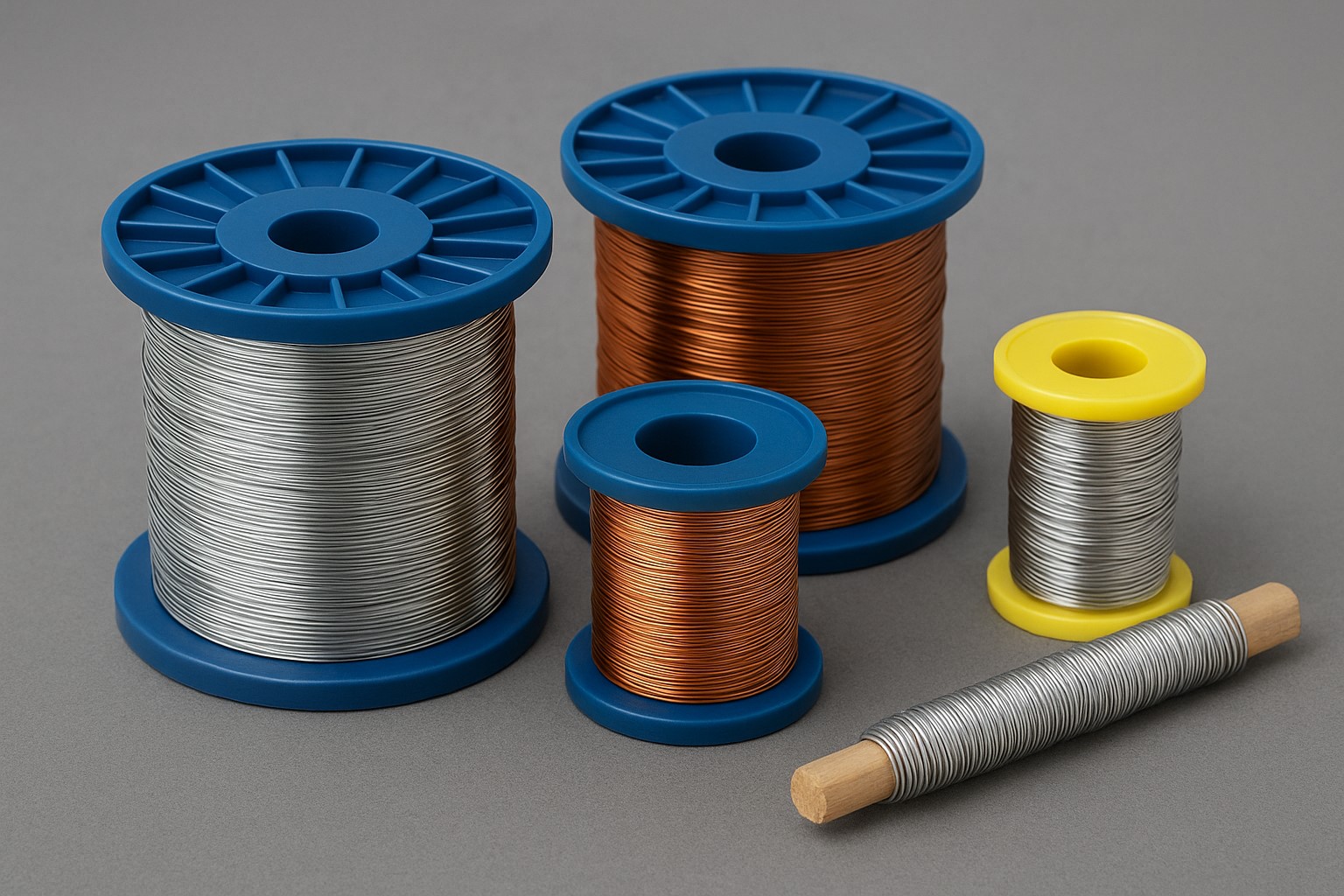

Wire Drawing

In a wire drawing mill, thick metal rod – such as copper, aluminum, or steel – is first cleaned and coated with a lubricant carrier. The rod is then pulled through a series of progressively smaller dies, which gradually reduce its diameter while increasing its length.

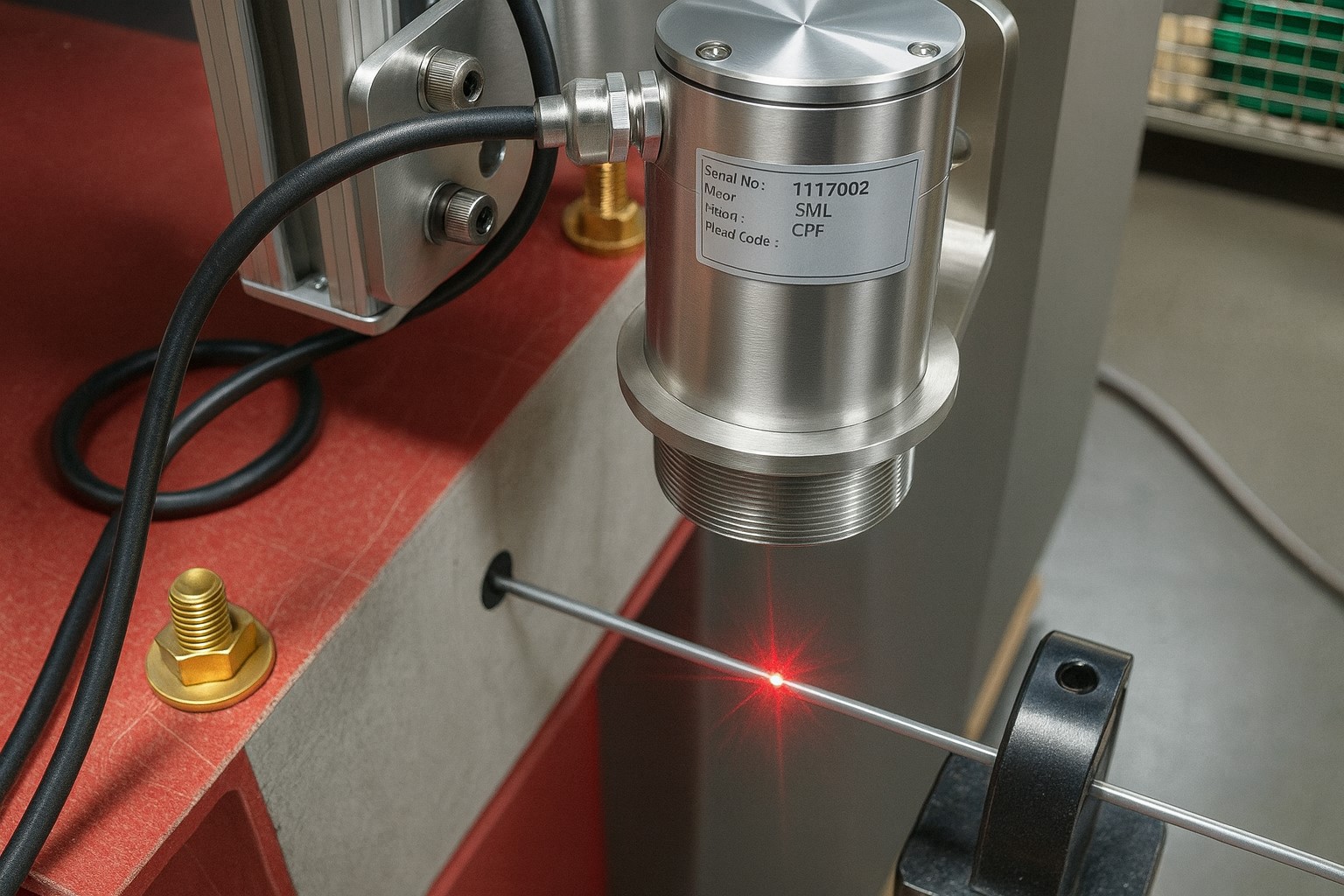

Tall Oil

Tall oil is a natural by-product of the kraft pulping process. It is obtained by collecting and acidulating soap that forms in the black liquor. The resulting crude tall oil can then be refined into valuable chemicals and resins. (Image courtesy of Rottneros AB)

Products

Our solutions — engineered to deliver and optimized for performance.

Alu Treater

Alu Treater stabilizes conductivity and removes contaminants in aluminum cold rolling oils, extending filter life, improving strip quality, and reducing costs. All this is achieved without chaninging the oil or the filtration system.

Emulsion Treatment

Emulsion Treatment breaks down stubborn water-in-oil emulsions and bilge water. This enables efficient oil–water separation in order to recover clean oil, clarify water, and reduce waste.

Lube Line

Lube Line is a line of water-soluble synthetic lubricants. Used in wire drawing applications, Lube Line ensures cleaner processing, longer equipment life, and an optimal surface finish on the final wire.

Pinola Chemical

Pinola Chemical prevents calcium sulphate deposits during tall-oil acidulation, keeping equipment clear and ensuring stable, continuous production.